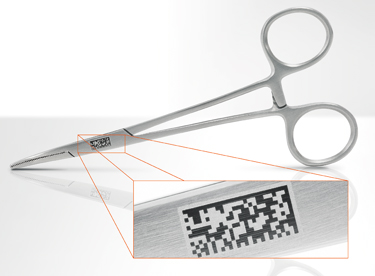

Global standards for automatic identification provide an opportunity to make the healthcare supply chain safer as well as more efficient and accurate. Healthcare regulators and trading partners have realised that a global standardised identification system from manufacturer to patient treatment is imperative to comply with the increasing need for product traceability around the world. The GS1 System, globally endorsed by the healthcare community, is the most widely used identification system worldwide with more than 5 billion transactions per day. Built on a foundation of identification keys (such as the Global Trade Item Number or GTIN) and attributes (such as a batch/ lot number, expiry date, unique serial number etc.), it is uniquely suited to meet the needs of the healthcare industry.

Read more here MC07_GS1_Datamatrix